Fittings

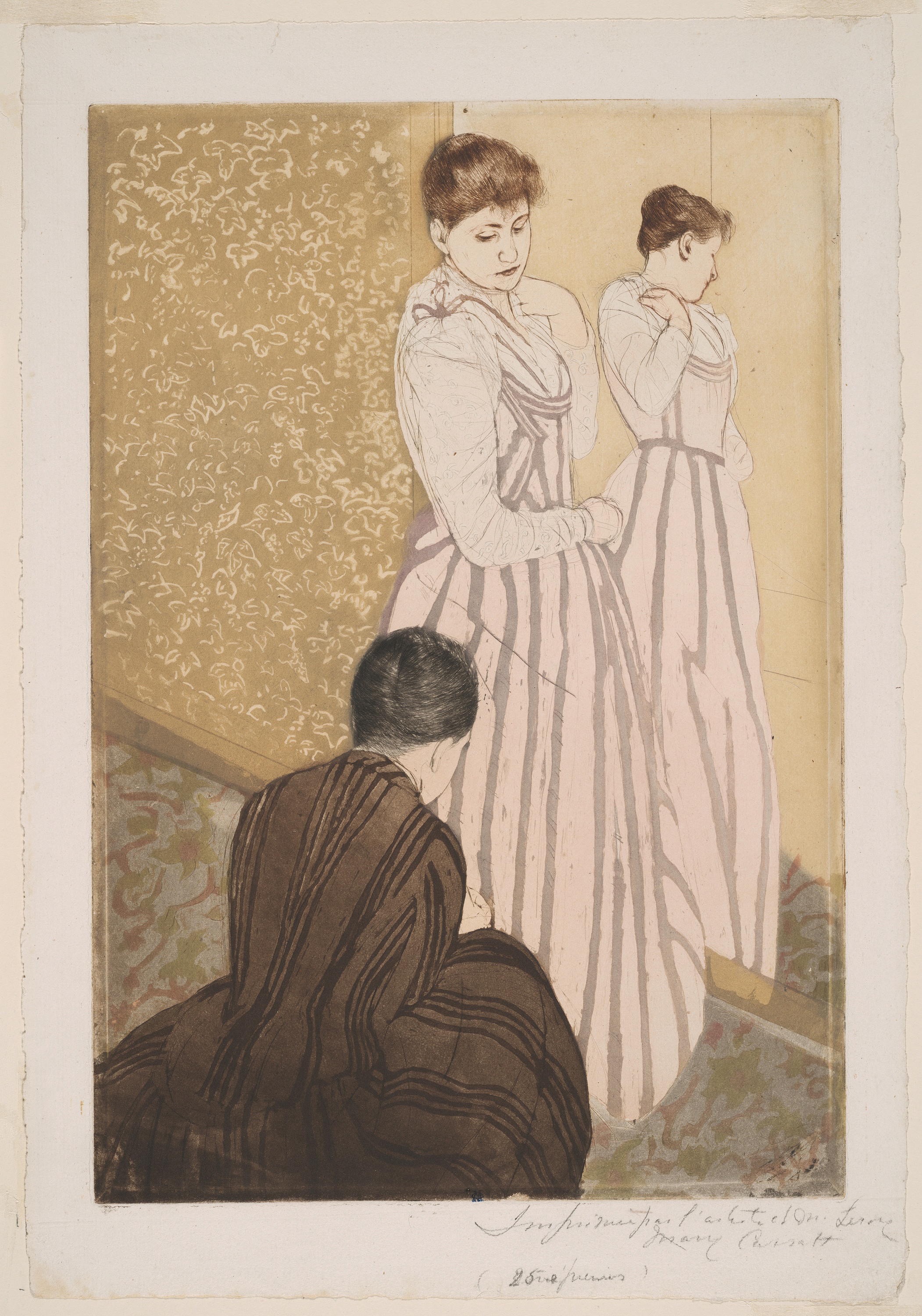

Mary Cassatt: The Fitting (1890–91)

" … we might just as well be satisfied with the process destined to ultimately delight us."

In the house I grew up in, the music room—the room with the piano and also the room where 'us kids' could isolate to practice our band instruments—doubled as the fitting room for my mom's seamstress business. She'd make wedding dresses and ball gowns, and she'd escort a steady stream of society ladies into that room to try on their new creations. Some pieces required multiple Fittings, as completion took on an iterative nature. There are apparently many elements of dress construction which can only be approximated without the person who will wear it present. Custom made clothing demands a great deal of patience. My mom would pin together seams for later sewing. Occasionally, she'd have to pull out the old seam ripper to completely redo something. It all seemed so exacting.

These childhood experiences tipped me off to the fact that complicated constructions do not come in one-and-done forms. Others were not so fortunate. When I took a job helping to implement software packages, not all of the sponsors of these efforts seemed prepared for the requisite iteration. They'd command delivery by such-and-such a date and we'd make a great effort only to usually fall a little short, discovering one seam or another needing ripping out and resewing before anyone would be wearing that system to any cotillion. It was just a law of nature, not evidence of any shortcoming, though the lesser-evolved sponsors could always make incriminating comments about how their colleagues in other companies were never treated to our bait and switch tactics. We'd halve the distance to finished on the next iteration, then halve it again on the following one, always engaging in Zeno's Paradox as our sole means of delivering anything, always delivering more Fittings than finished systems. So it always went. So it always would.

Yesterday morning, our Blacksmith, Ben, had planned the long-awaited installation of our custom-made front porch stair railings, wrought iron monsters designed and constructed specifically for our front porch steps. Ben had carefully measured and planned, visiting twice to make certain he'd measured correctly, even bringing over a piece of the initial construction for a Fitting one morning. This day, I finally see the finished products and they're every bit as beautiful as I'd hoped, twisted steel legs and rails gently swooshing. They looked perfect. The first one fit fine at the top and middle, but its bottom leg was over an inch shorter than needed. Its mirror on the opposite side of the same steps, fit almost perfectly. We were baffled. The hind legs of both measured precisely the same length, so why was one deficient? We decided that perhaps the swooping curve of the top rail was not precisely duplicated in both. Whatever the cause, they would go back to the shop for another fabrication iteration. Both were found flawed, but it was just a Fitting.

Fitting

©2022 by David A. Schmaltz - all rights reserved

I proposed that maybe we could just use a spacer to make that railing fit. Ben considered this before replying that he only trades in one thing, his integrity. This creation, which is a work of art, his effort incarnate, had to be perfect. I watched as he swallowed the judgement this Fitting provided. He swallowed some pride along with some disappointment. He apologized several times, as if some error had been committed. I told him that this was not my first rodeo and that I knew how these things went, and that I could take whatever feedback came with this territory. We rescheduled implementation for Monday when we'll see whether we actually install or call that session another Fitting. We have infinity seemingly at our command. We could iterate until we're satisfied, and so we might just as well be satisfied with the process destined to ultimately delight us, Fittings all the way until we're finished.